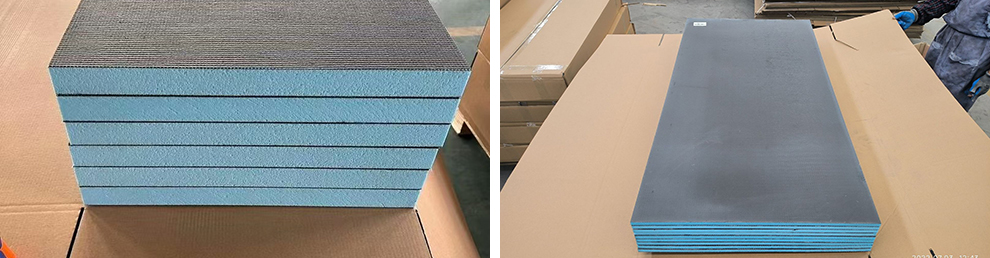

Wall Tile Backer Board

1.Zero seepage guarantee: one-piece molding waterproof structure + nano moisture-proof layer, humidity 99% of the environment without fear of mildew

2.Ultra-hardcore load-bearing: compressive strength ≥ 350kg / ㎡, 2 times more than the national standard, to eliminate tile drumming and falling off!

3. Extremely fast construction: dry straight paving without leveling, 1 day to complete the whole house wall, efficiency increased by 80%.

4. Super durability: good crack resistance.

5. All-around adaptability: support ultra-thin rock slab / slab tile paving, compatible with invisible access ports, intelligent mirror cabinet buried!

Product introduction:

Our wall tile backer board is engineered specifically for wall tile installations. This innovative substrate provides ideal flatness and support for various wall tiles, ensuring professional installation results.

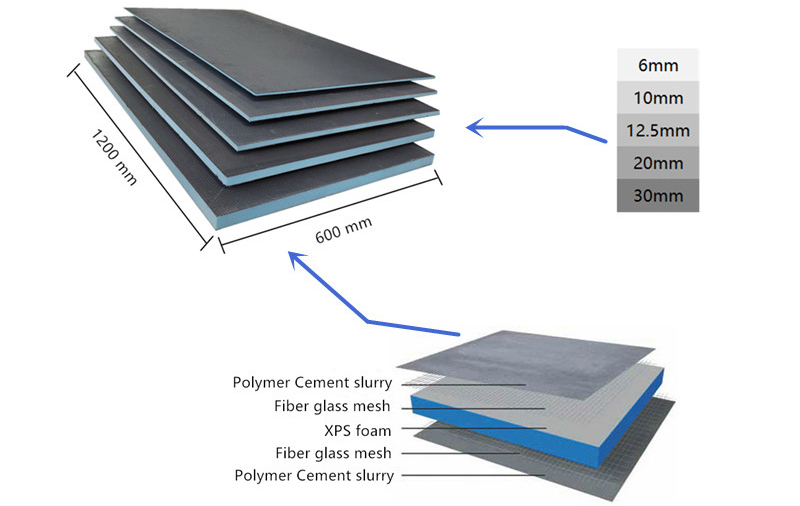

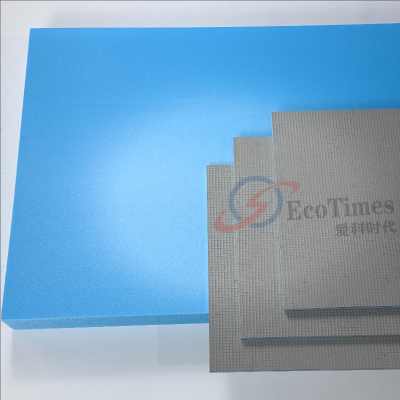

Wall tile backer board is a revolutionary wall base material, made of XPS extruded board + alkali-resistant fiberglass mesh cloth + polymer mortar, which is both lightweight and ultra-high load-bearing capacity, and completely solves the traditional plastering drums and cracking pain points. Its waterproof and moisture-proof integration characteristics, with quick installation and maintenance-free process, can be directly paved tiles / stone, construction efficiency increased by 80%, is the all-round base material for indoor and outdoor wall decoration, especially for high humidity, high load scenarios.

Product parameters:

Item | Performance Requirements |

Surface water absorption/(g/m2) | ≤300 |

Impermeability | No water penetration on the inside of the reinforcing layer |

Impact resistance/J grade | 10 |

Bending load/N | ≥1000 |

Interlayer bond strength/MPa | ≥0.40 |

Shear strength/kPa | ≥500 |

Moisture deformation/% | ≤0.07 |

Product application:

✅ Home space: kitchen, bathroom, balcony walls, moisture resistance and mold life of more than 20 years.

✅ Commercial projects: hotel lobby, shopping mall walls, subway stations and other high-traffic areas, load-bearing durability up to 2 times the national standard.

✅ Construction renovation: old walls are covered directly without demolition, saving 75% of construction waste and labor costs.

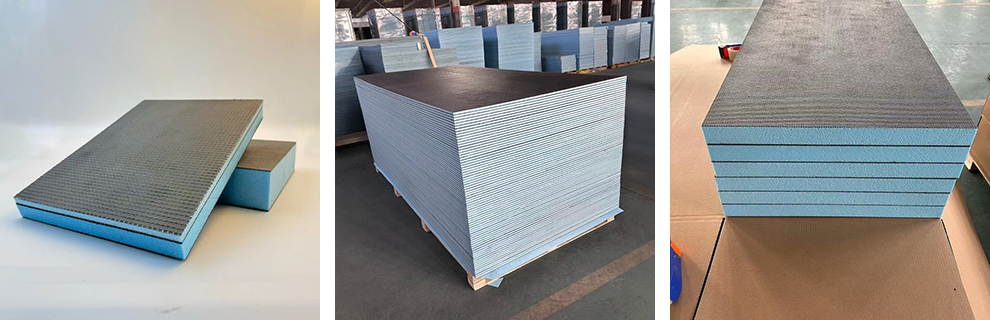

Packaging and shipping:

📦 Standard specification: standard specification: 1200×2400mm can be customized, thickness 95/120/200/300/500mm can be customized.

📦 Protection scheme: anti-collision corner guard + winding film + wooden pallet, anti-pressure and moisture resistance, support cross-border transportation.

Installation process:

1️⃣ Substrate treatment: Clean the wall surface to ensure it is solid and flat, free from oil and floating ash;

2️⃣ Cutting and adapting: The backing board can be cut to meet specific requirements and supports modeling for right angles and curved surfaces;

3️⃣ Fixing substrate: Use a special binder combined with expansion anchor bolts for dual fixing, and apply waterproof reinforcement tape at the joints;

4️⃣ Finish construction: directly thin paste wall tiles after 24 hours, without cement mortar leveling layer.

Company Strength:

As a source manufacturer, we have 100,000 square meters of intelligent production base, equipped with automatic extrusion line and quality inspection laboratory, with an annual production capacity of more than 5 million square meters. Through ISO9001, green building materials certification testing, products have been successfully applied to national projects, and provide customized solutions and full-cycle technical guidance, from R & D to after-sales escort, to help customers reduce costs and increase efficiency.