EPS And XPS

1. Cost-Effective Solution - Lower material cost while maintaining good insulation performance

2. Excellent Thermal Insulation - R-value remains stable over time

3. Lightweight Structure - Easy to handle and install, reducing labor costs

4. Breathable Material - Allows moisture diffusion, preventing condensation

5. Versatile Applications - Suitable for walls, packaging, and lightweight fills

6. Eco-Friendly Option - 100% recyclable with lower production energy

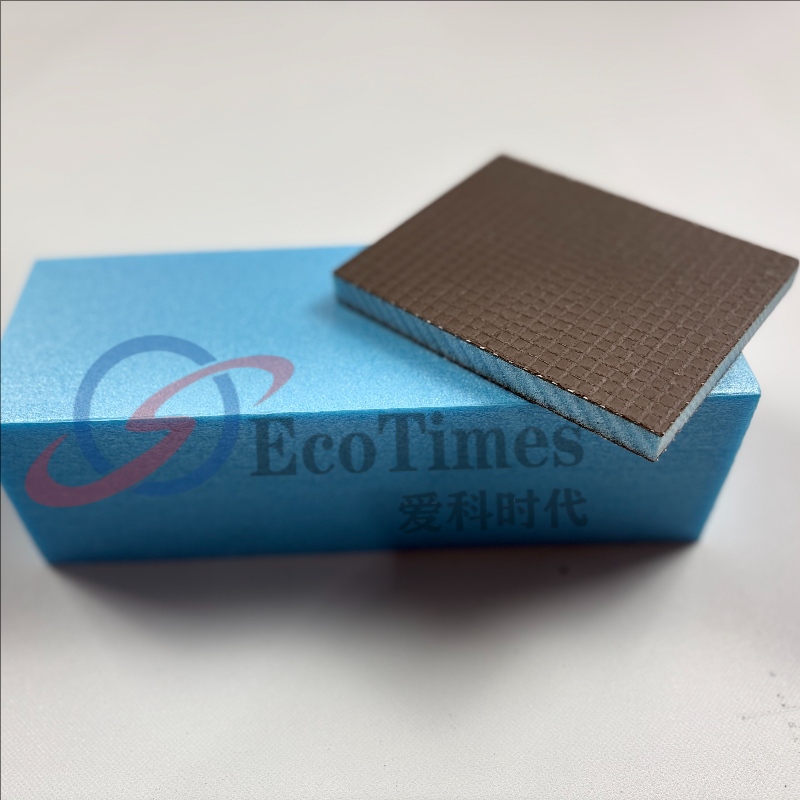

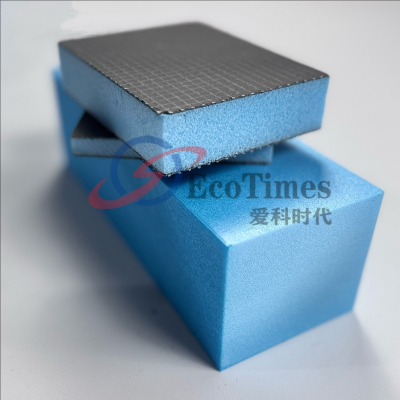

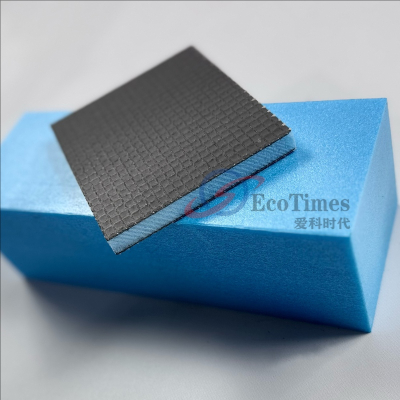

Product Introduction:

EPS insulation board is made by expanding polystyrene beads into molded blocks, creating a lightweight yet effective insulation material. With its unique bead structure, EPS provides reliable thermal performance for wall insulation and backer board applications. The material's breathability makes it ideal for building envelopes where moisture management is crucial, while its cost-effectiveness ensures budget-friendly project solutions.

Product Parameters:

| Density | 15-30 kg/m³ |

| Compressive Strength | 70-250 kPa |

| Thermal Conductivity | 0.032-0.038 W/(m·K) |

| Water Absorption | 2-4% by volume |

| Operating Temperature | -50°C to +75°C |

Product Application: