Bathroom Tile Backer Board

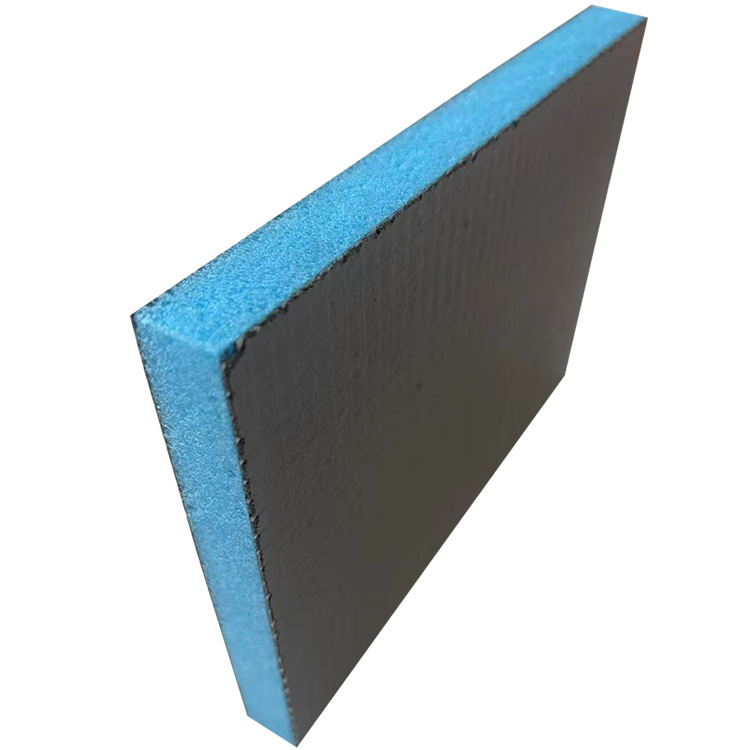

1. Superior Water Barrier- Engineered core blocks 100% moisture penetration

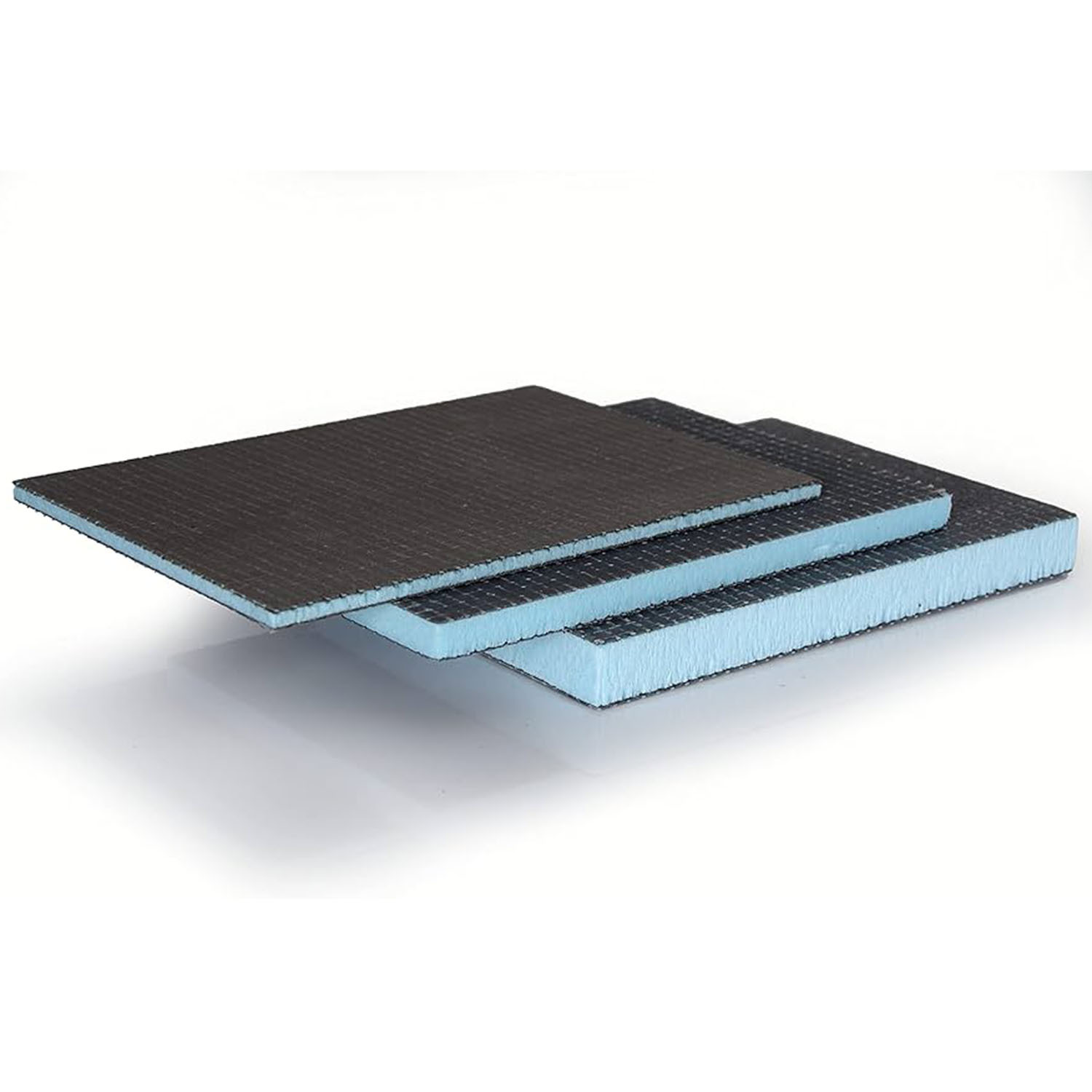

2. Structural Integrity- Reinforced fiber matrix withstands heavy tile loads

3. Thermal Stable - Won't expand/contract with humidity fluctuations

4. Mold Defense - Inorganic composition prevents microbial growth

5. Installation Ready - Pre-primed surface accepts thinset immediately

Product introduction:

Our cementitious backer board utilizes advanced polymer-fiber technology,creating an impermeable substrate that outperforms traditional cement boards. The integrated moisture barrier eliminates need for separate membranes.

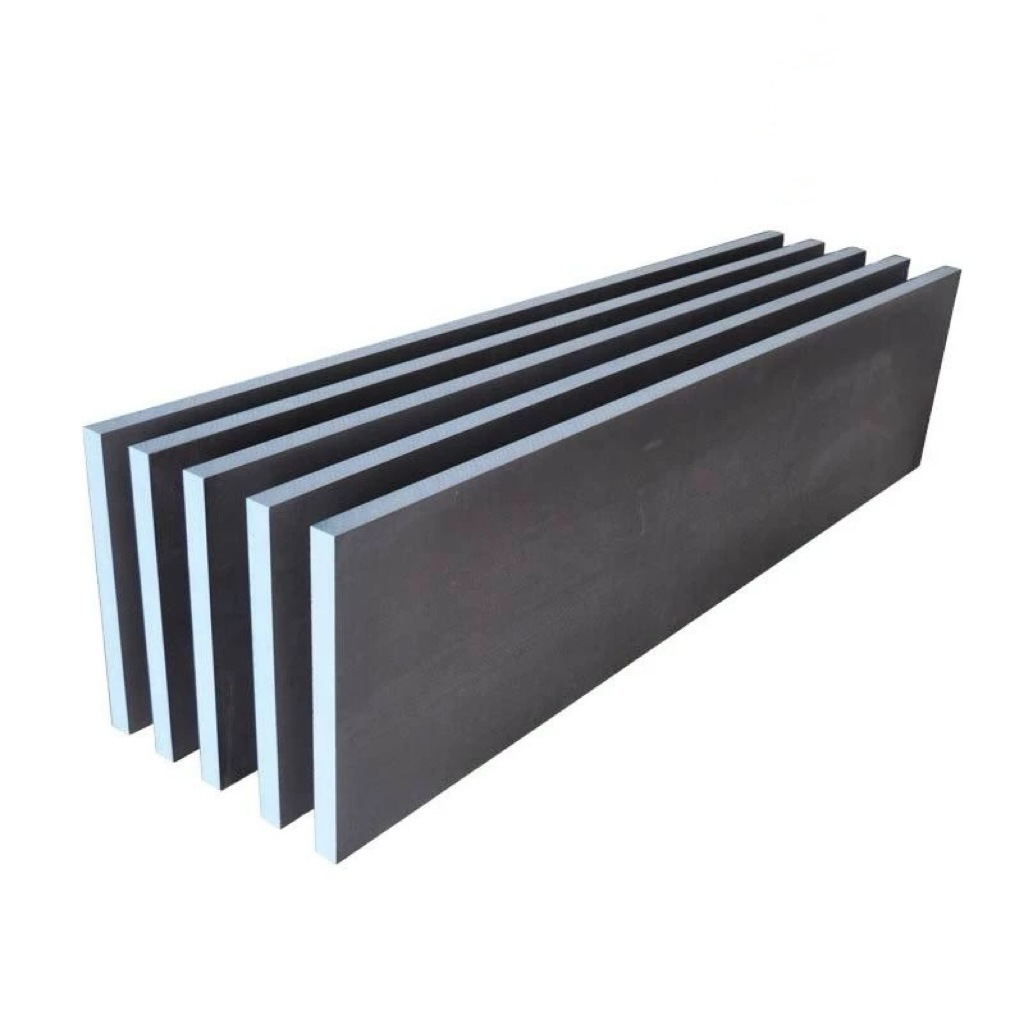

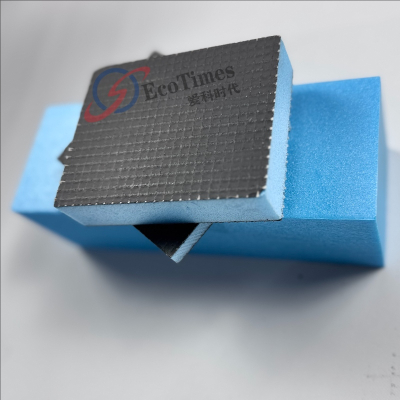

Bathroom tile backer board is an all-round substrate specially developed for high humidity environments. It is made of XPS extruded board + alkali-resistant fiberglass mesh cloth + polymer mortar, which can completely block the penetration of water vapor and overcome the problems of mildew and drumming of the traditional cement base. Its lightweight and high-strength characteristics, with quick installation and maintenance-free process, cut and pave tiles directly, construction efficiency increased by 60%, perfectly adapted to the shower area, niches and other complex surfaces, to create a long-lasting dry bathroom space.

Product parameters:

Item | Performance Requirements |

Surface water absorption/(g/m2) | ≤300 |

Impermeability | No water penetration on the inside of the reinforcing layer |

Impact resistance/J grade | 10 |

Bending load/N | ≥1000 |

Interlayer bond strength/MPa | ≥0.40 |

Shear strength/kPa | ≥500 |

Moisture deformation/% | ≤0.07 |

Product application:

✅ Home bathroom: shower wall/floor, bathtub surround, sink back wall

✅ Commercial public installation: hotel bathroom, gym wet area, spa locker room and other high-frequency water scenes

✅ Old house renovation: no need to remove the old bricks, direct coverage construction, saving 70% of the construction period and demolition costs.

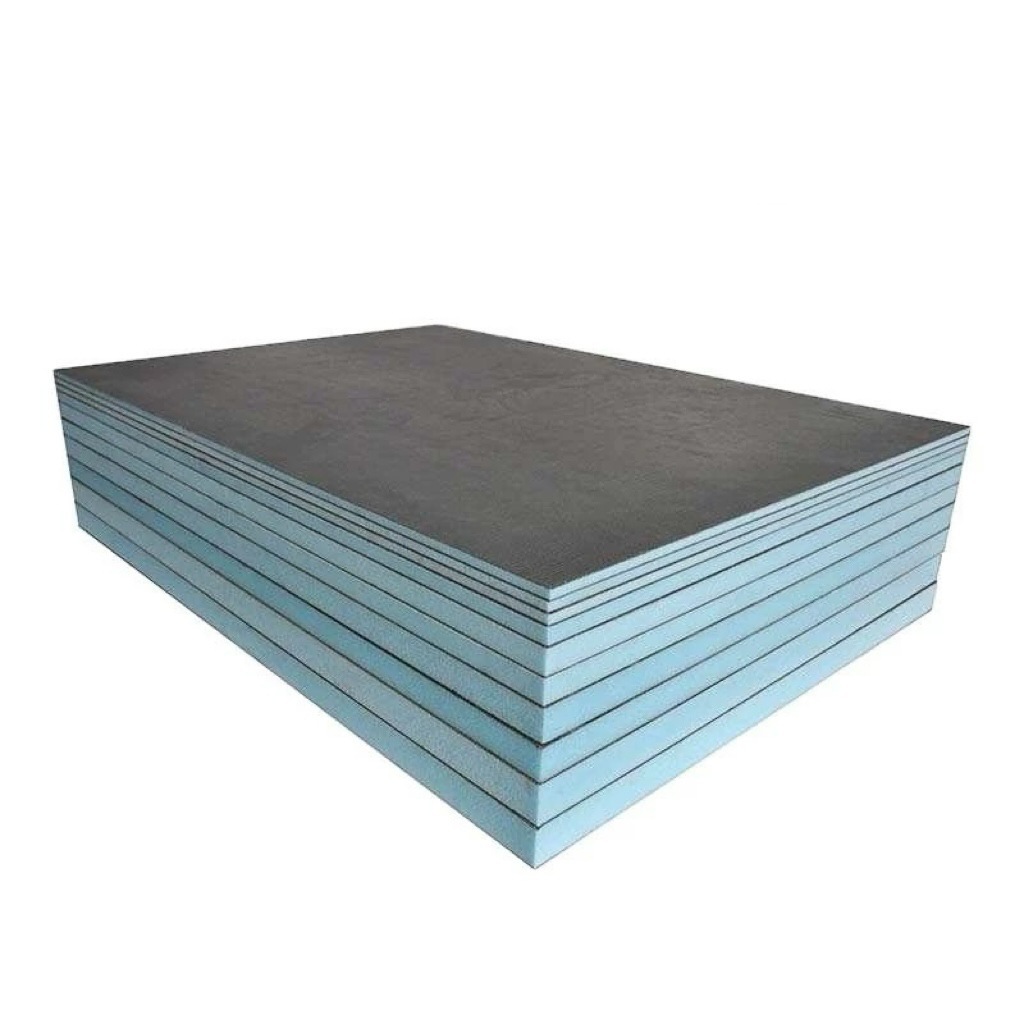

Packaging and shipping:

📦 Standard specification: standard specification: 1200×2400mm can be customized, thickness 95/120/200/300/500mm can be customized.

📦 Protection scheme: anti-collision corner guard + winding film + wooden pallet, anti-pressure and moisture resistance, support cross-border transportation.

Installation process:

1️⃣ Substrate treatment: clean the wall until flat and dust-free, repair cracks;

2️⃣ Precise cutting: cut the backing plate according to the size, curved/shaped area can be hot bending and shaping;

3️⃣ Fixing substrate: special structural adhesive + anti-rust screws double fixing, waterproof tape at the joints;

4️⃣ Tile laying: 24 hours after the use of thin paste method directly laying tiles, without cement plaster layer.

Company Strength:

As a source manufacturer, we have 100,000 square meters of intelligent production base, equipped with automatic extrusion line and quality inspection laboratory, with an annual production capacity of more than 5 million square meters. Through ISO9001, green building materials certification testing, products have been successfully applied to national projects, and provide customized solutions and full-cycle technical guidance, from R & D to after-sales escort, to help customers reduce costs and increase efficiency.