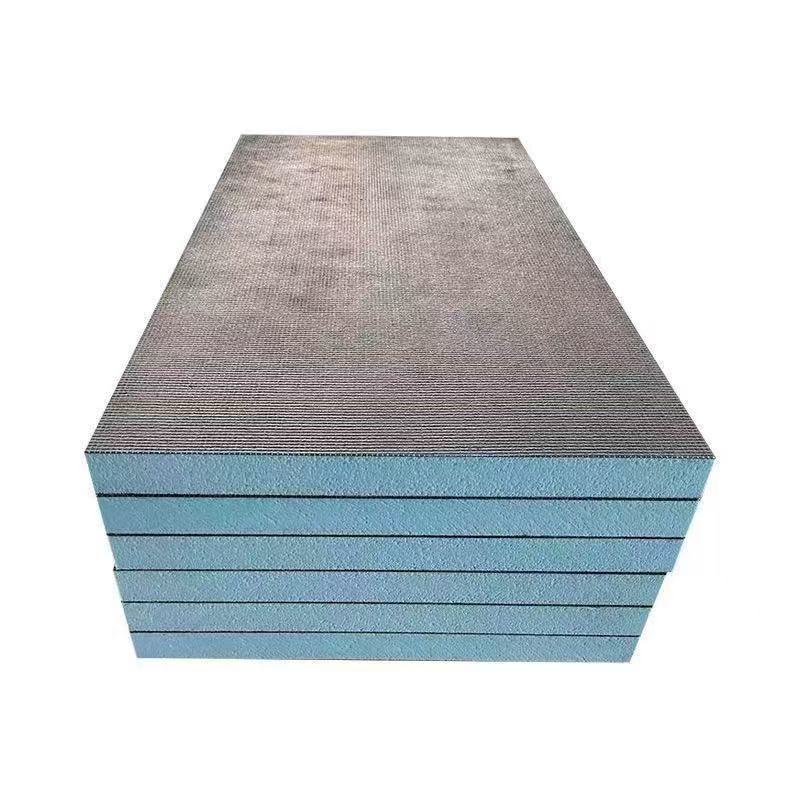

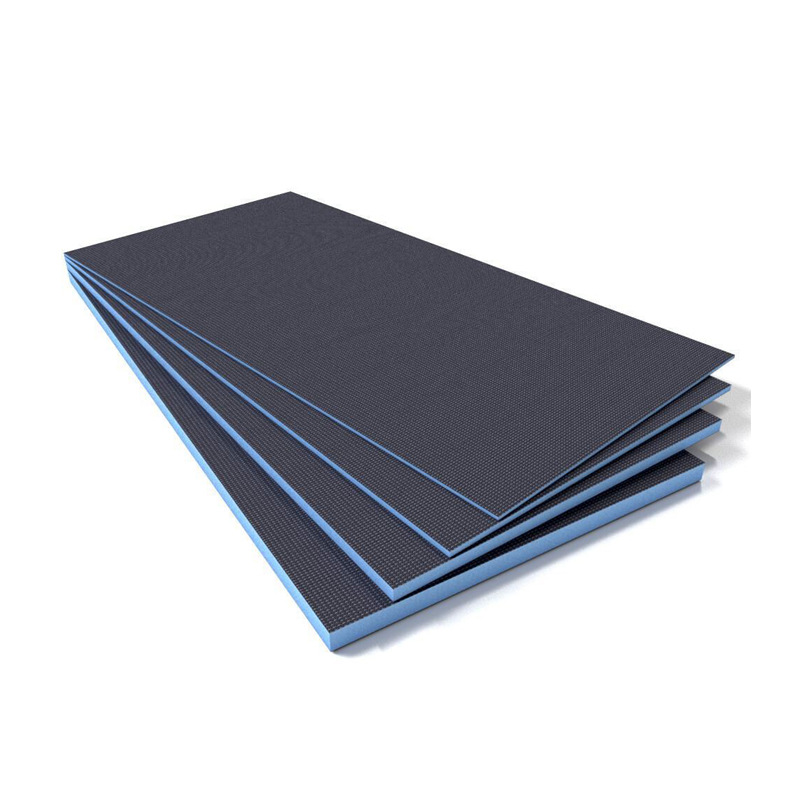

Underfloor Heating Tile Backer Board

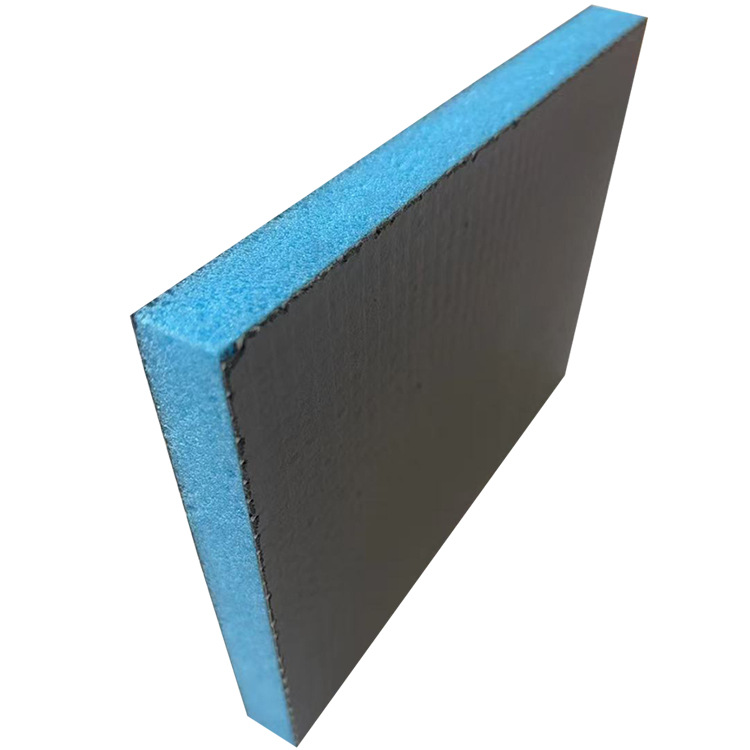

1.High-efficiency thermal conductivity: XPS extruded board + alkali-resistant fiberglass mesh cloth + polymer mortar production, thermal conductivity of 2.8W / (m-K), 40% faster heating, 30% lower energy consumption.

2.Heat and pressure resistance: -30 ℃ ~ 120 ℃ thermal cycling zero deformation, load-bearing ≥ 500kg / ㎡, to eliminate floor heating drum cracking.

3.Environmental protection and safety: 100 ℃ continuous heating without volatiles.

4.Dry fast installation: modular assembly without cement, floor heating layer thickness reduced by 50%, the construction period compressed to 1 day.

5.Moisture and noise reduction: blocking water vapor from returning, footstep noise reduction of 28dB.

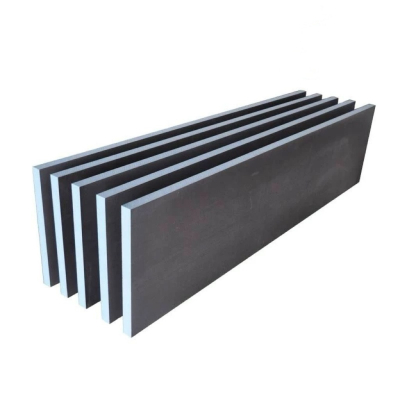

Product introduction:

Floor heating tile backing board is a revolutionary substrate designed for high-efficiency floor heating system, which is made of XPS extruded plastic board + alkali-resistant fiberglass mesh cloth + polymer mortar, and it can speed up the heating by 60% and reduce energy consumption by 35% compared with the traditional cement leveling layer. Its compressive and heat-resistant performance completely solves the hidden danger of floor heating drumming and cracking, combined with the dry fast installation process, to realize the floor heating pipeline pre-burial and tile paving synchronization, to create an energy-saving, safe and stable ground system.

This innovative underfloor heating substrate combines thermal transfer,insulation and load-bearing functions.

Product parameters:

Item | Performance Requirements |

Surface water absorption/(g/m2) | ≤300 |

Impermeability | No water penetration on the inside of the reinforcing layer |

Impact resistance/J grade | 10 |

Bending load/N | ≥1000 |

Interlayer bond strength/MPa | ≥0.40 |

Shear strength/kPa | ≥500 |

Moisture deformation/% | ≤0.07 |

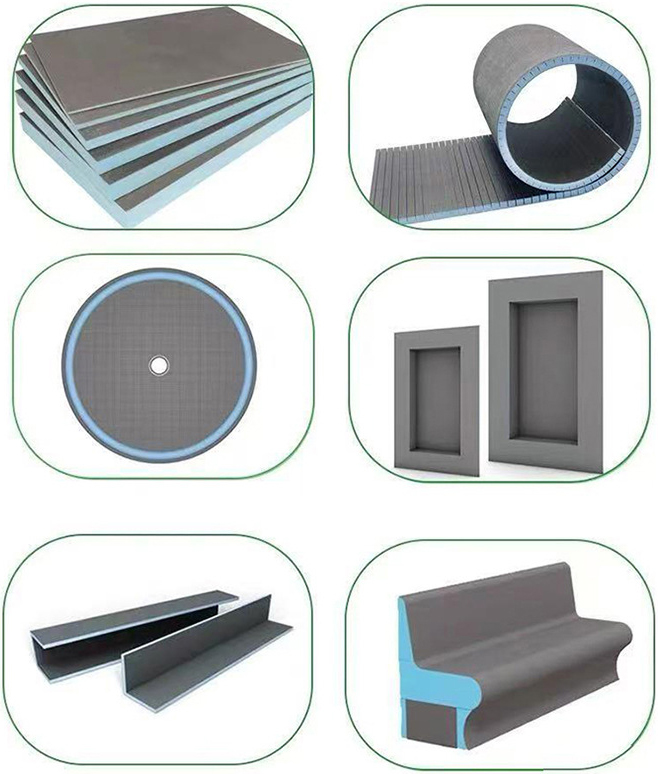

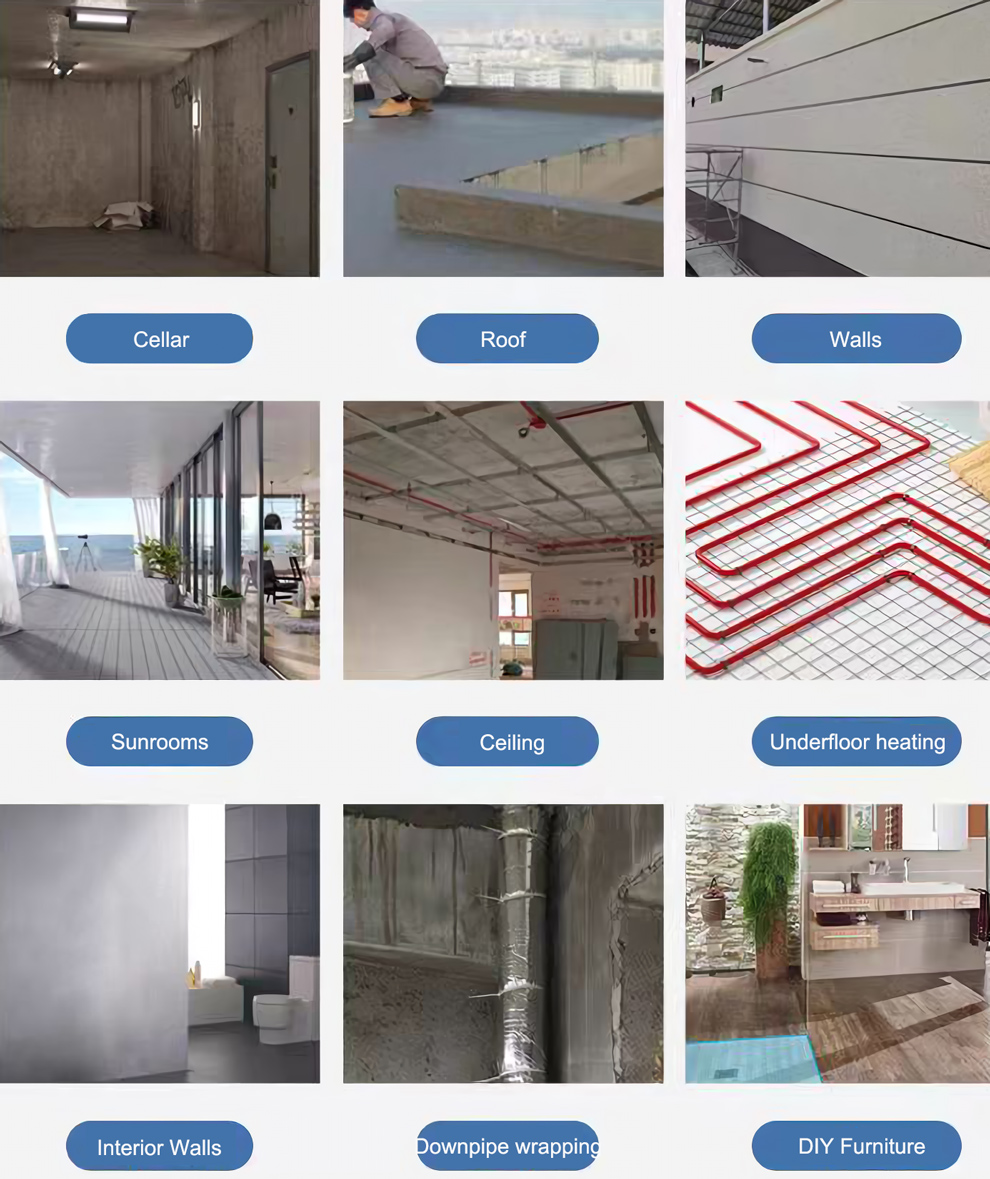

Product application:

✅ Residential areas: kitchen, bathroom, and balcony walls, with moisture resistance and mold prevention lasting over 20 years.

✅ Commercial applications: hotel lobbies, shopping mall walls, subway stations, and other high-traffic areas, with load-bearing durability up to twice the national standard.

✅ In construction renovation projects: old walls can be directly covered without the need for demolition, thereby saving 75% of construction waste and labor costs.

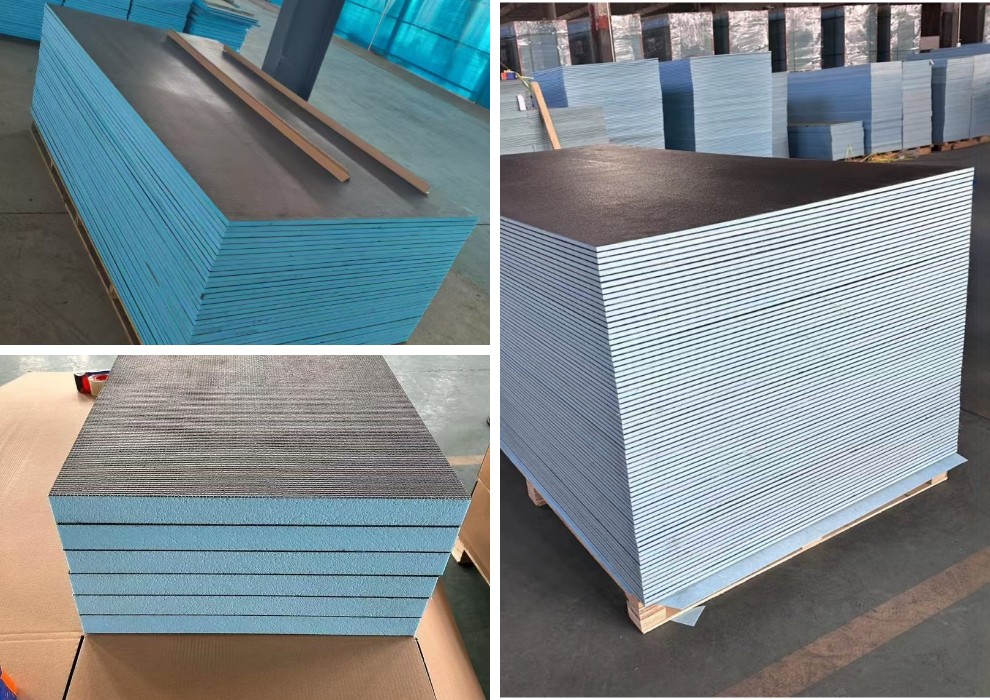

Packaging and shipping:

📦 Standard specification: The standard size is 1200×2400mm, which can be customized. The thickness options of 95/120/200/300/500mm are also customizable.

📦 Protection scheme: anti-collision corner guard + winding film + wooden pallet, anti-pressure and moisture resistance, support cross-border transportation.

Installation process:

1️⃣ Substrate treatment: clean the wall surface to solid and flat, no oil floating ash;

2️⃣ Cutting and adapting: cut the backing board according to the demand, support right angle/curved surface modeling;

3️⃣ Fixing substrate: special binder + expansion anchor bolt double fixing, waterproof reinforcement tape at the joints;

4️⃣ Finish construction: directly thin paste wall tiles after 24 hours, without cement mortar leveling layer.

Company Profile:

As a source manufacturer, we possess a 100,000-square-meter intelligent production base, complete with an automatic extrusion line and a quality inspection laboratory, boasting an annual production capacity of over 5 million square meters. Through ISO9001, green building materials certification testing, products have been successfully applied to national projects, and provide customized solutions and full-cycle technical guidance, from R & D to after-sales escort, to help customers reduce costs and increase efficiency.