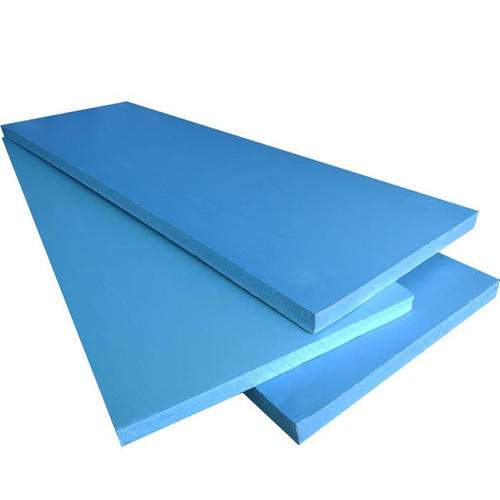

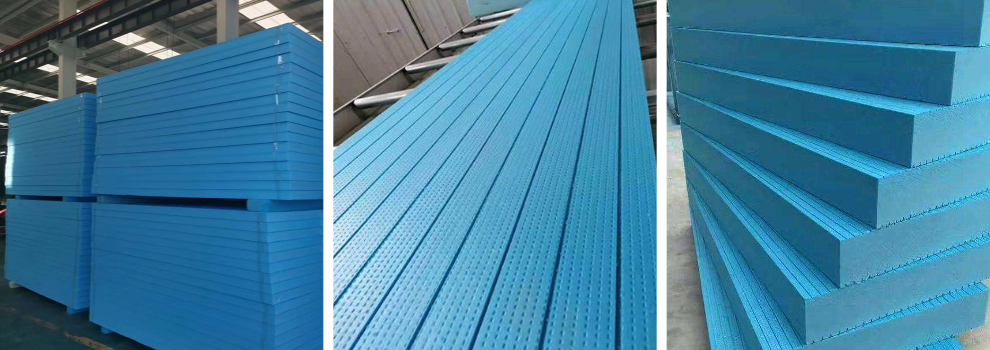

Extruded Polystyrene Board

1.Efficient heat preservation: closed cell structure + ultra-low thermal conductivity (≤ 0.028W/m-K), energy saving rate is 30% higher than traditional EPS foam, preferred for cold storage/exterior wall of buildings.

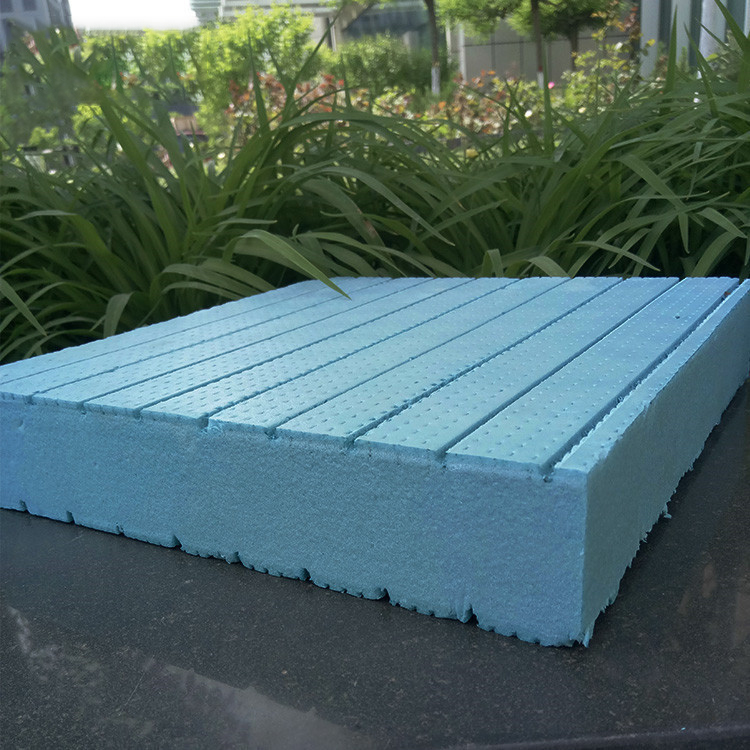

2.King of compression resistance: 200-700kPa compressive strength, heavy vehicles do not deform when crushed, subway/floor heating grassroots dedicated

3.Water-repellent and moisture-proof: water-absorption rate <1%, no loss of performance after 48 hours of soaking, zero permeability guarantee for basement/river bank project.

4.Ultra-long life: stable molecular structure, anti-aging test 50 years strength retention rate of> 95%, maintenance-free cycle doubled.

5.Environmental protection and energy saving: 100% recyclable raw materials, certified by China Green Building Material, carbon footprint reduced by 80% compared with concrete.

6.Lightweight and quick installation: self-weight is only 1/10 of the cement layer, can be cut on-site, shortening the construction period by 60% and reducing the comprehensive cost by 40%.

Product introduction:

Extruded polystyrene foam board (XPS board) is a closed-cell thermal insulation material made of polystyrene resin, continuously extruded and molded by a special process, which has the core advantages of high compression resistance, low thermal conductivity, moisture resistance and corrosion resistance. As the preferred material in the field of building energy saving, XPS board is widely used in the fields of exterior wall insulation, roof insulation, cold storage flooring, municipal engineering and so on with its excellent thermal insulation performance and long-life characteristics, especially suitable for scenes with strict requirements on load-bearing and moisture-proofing.

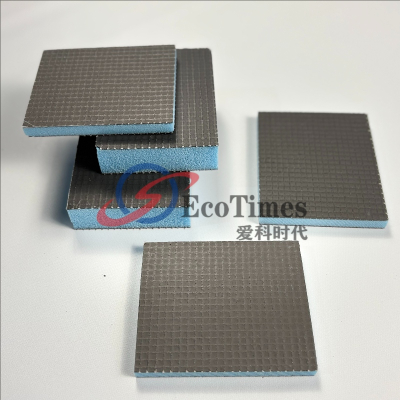

The extruded polystyrene board, as a high-quality building thermal insulation material, can also be used as a backing board.

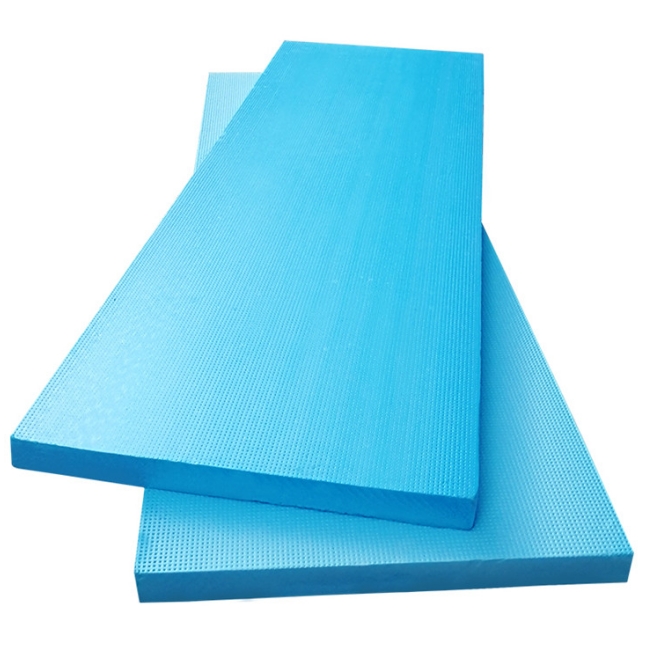

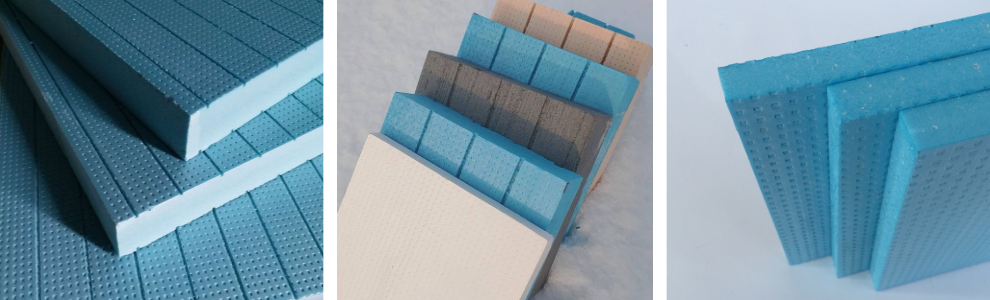

It is extruded and formed by a special process, with a continuous and uniform closed-cell honeycomb structure, which endows the product with good thermal insulation, compressive resistance and waterproof performance.

Product parameters:

Specifications are mostly 1200 * 600mm, thickness 95/120/200/300/500mm can be customized, density 30-45kg/m³, compressive strength ≥ 150KPa, thermal conductivity as low as 0.028W/(m-K).

Product application:

Extruded polystyrene foam board are installed in the building exterior wall insulation system through the combination of bonding mortar and mechanical anchoring to ensure a close fit with the grass-roots wall; during the construction of the cold storage flooring, staggered-seam paving and waterproofing layer are used to effectively isolate the cold bridge effect. The installation process needs to ensure that the grass-roots level, the use of professional cutting tools to process the plate, the joints with aluminum foil tape sealing, to enhance the overall airtightness.

Packaging and shipping:

Extruded polystyrene foam board with moisture-proof film + wooden pallet standardized packaging. Shipments throughout the coverage of waterproof protection, support for truckload / LTL logistics, nationwide rapid response to protect the progress of the project.

Company Strength:

As a source manufacturer of extruded polystyrene foam board, our company has a fully automated XPS extrusion production line, with an annual production capacity of more than 5 million square meters, through the ISO9001 quality system certification, green building materials certification, product testing is strictly in line with GB/T 10801.2 standards. Relying on independent research and development formulas and large-scale production advantages, we can provide customers with cost-effective customized extrusion services, and at the same time equipped with a professional construction guidance team, from production to delivery of the whole process of escort, to help the high-quality development of green building!