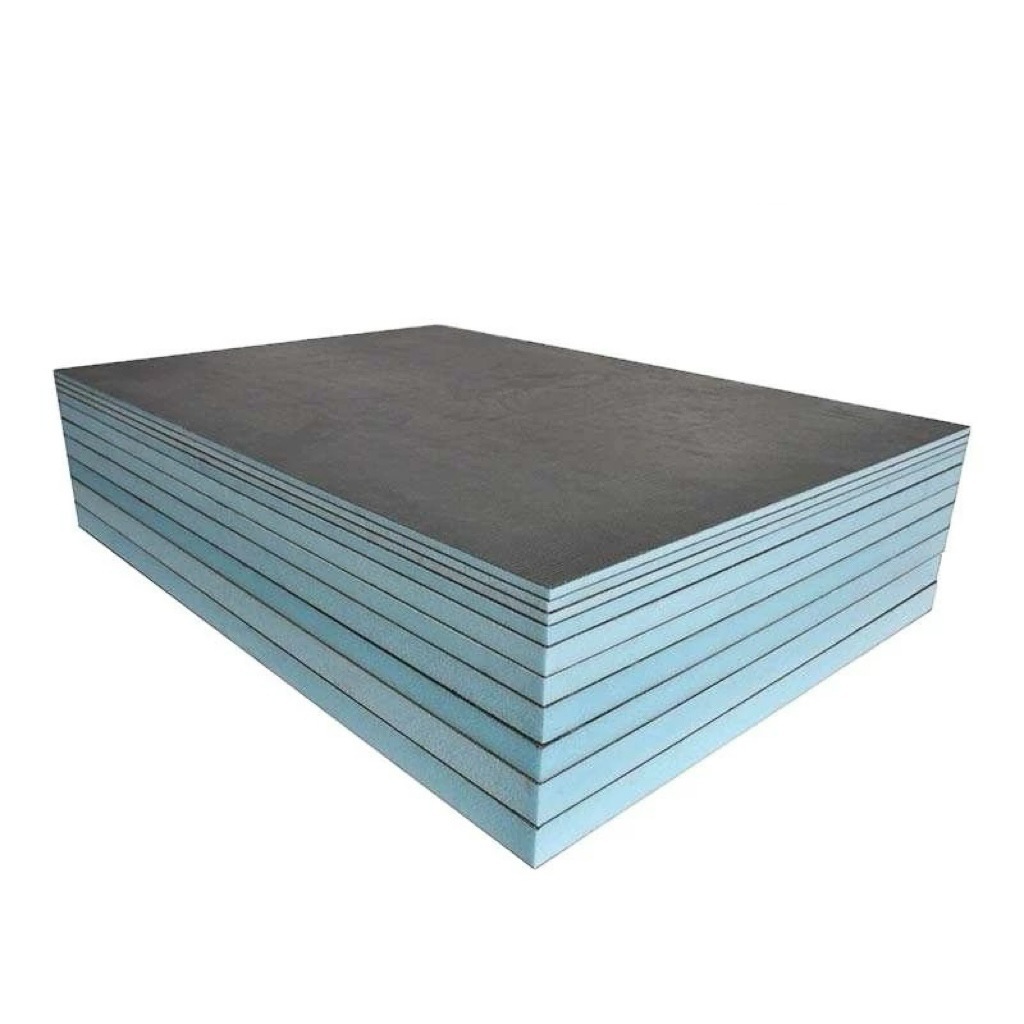

Waterproof Tile Backer Board

1.Drip does not seepage: composite waterproof structure, 48 hours of immersion without infiltration, the end of moisture hidden trouble.

2.Ultra-strong load: vertical load-bearing ≥ 600kg / ㎡, impact resistance up to 3 times the national standard, the wall and floor general non-collapsing.

3.Second installation revolution: self-locking snap installation, without professional tools, single person 1 hour to complete 30 square meters paving.

4.Anti-corrosion and durability: 40℃~150℃ extreme environment without aging and cracking.

5.All scenes are compatible: bathroom/kitchen/basement all-round fit, compatible with tiles, rock slabs, marble and other 8 types of finishes.

Product introduction:

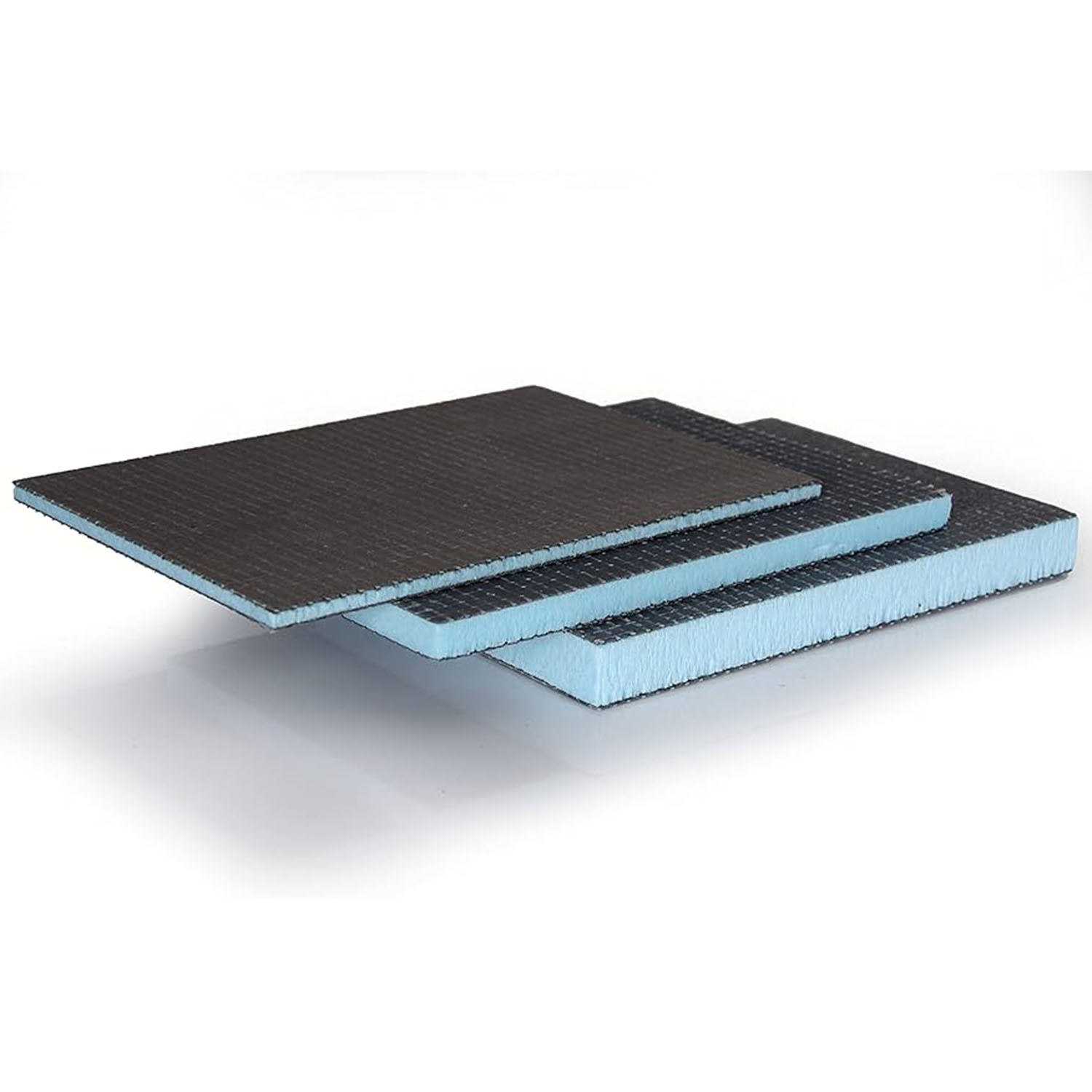

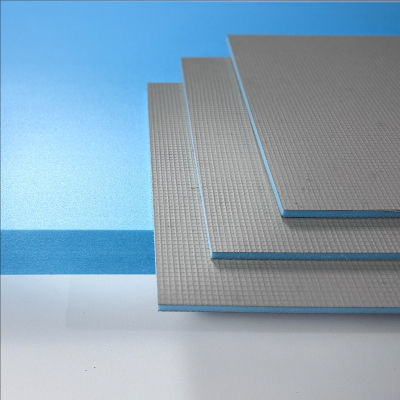

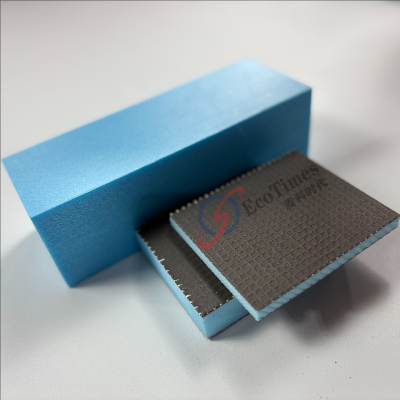

Waterproof tile backer board is a high-performance material specially developed for building damp-proofing and waterproofing projects. It is made of high-strength (high-density polyethylene) material, which is both lightweight and corrosion-resistant. As a core component in the field of building protection, the backing plate realizes efficient water conductivity and pressure resistance through unique structural design, which is perfectly suited for wet scenes such as basements, tunnels, pools, etc., and effectively extends the service life of the building. The anti-slip surface of the product can be seamlessly adhered to ceramic tiles, ensuring project safety and construction convenience.

Product parameters:

Item | Performance Requirements |

Surface water absorption/(g/m2) | ≤300 |

Impermeability | No water penetration on the inside of the reinforcing layer |

Impact resistance/J grade | 10 |

Bending load/N | ≥1000 |

Interlayer bond strength/MPa | ≥0.40 |

Shear strength/kPa | ≥500 |

Moisture deformation/% | ≤0.07 |

Product application:

Waterproof tile backer board are widely used in underground engineering, municipal pipeline corridors, green roofs and slope protection, and are particularly suitable for environments where hydrostatic pressure needs to be resisted for a long period of time. To install, the backing is simply laid flat on the substrate, reinforced with modular splices or special fixings, and the joints are sealed with adhesive. Its lightweight nature significantly reduces labor costs, and with its self-draining design, it can be used to quickly build an efficient moisture barrier system.

Packaging and shipping:

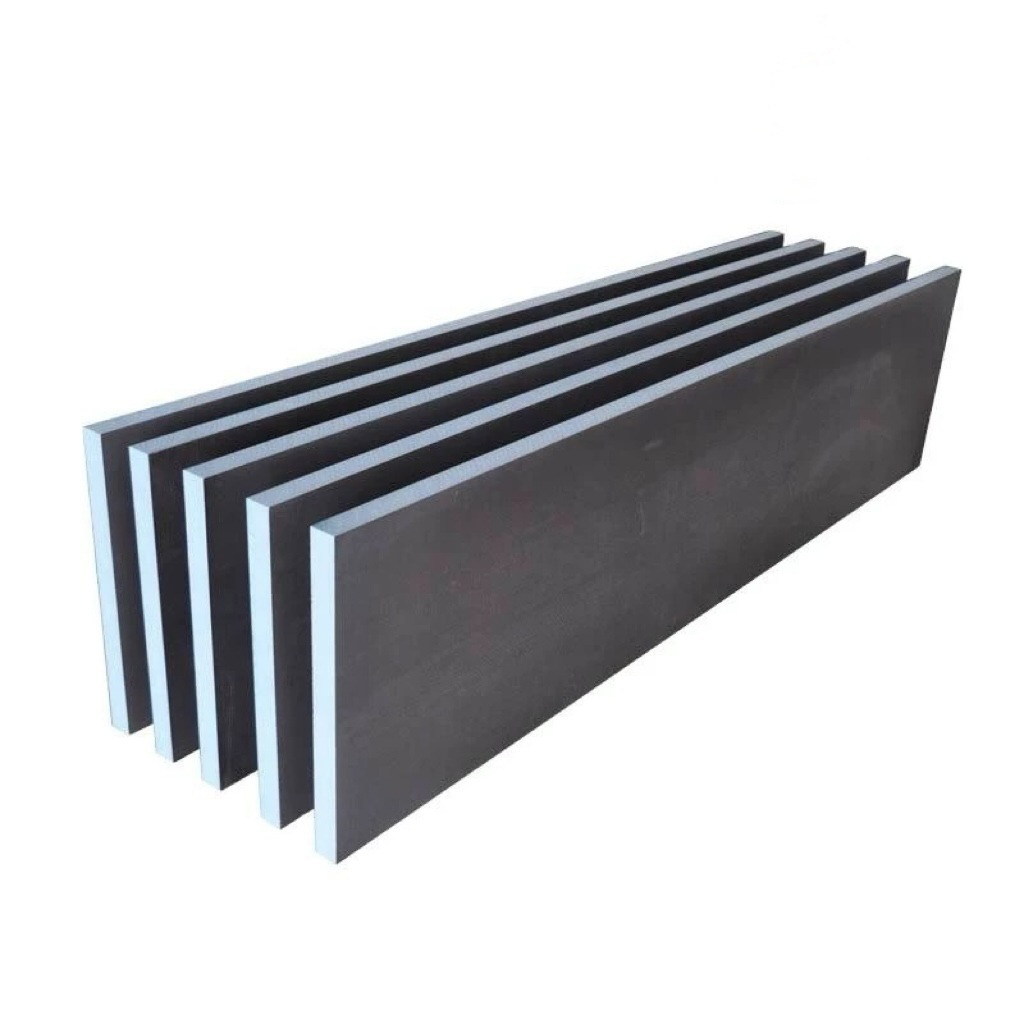

📦 Standard specification: standard specification: 1200×2400mm can be customized, thickness 95/120/200/300/500mm can be customized.

📦 Protection scheme: anti-collision corner guard + winding film + wooden pallet, anti-pressure and moisture resistance, support cross-border transportation.

Company Strength:

As a source manufacturer, we have an intelligent production base of 100,000 square meters, equipped with fully automatic production lines and quality inspection laboratories, with an annual production capacity of over 5 million square meters. Through ISO9001 and green building materials certification testing, our products have been successfully applied to national projects, and we provide customized solutions and full-cycle technical guidance, escorting customers from R&D to after-sales, helping them reduce costs and increase efficiency.