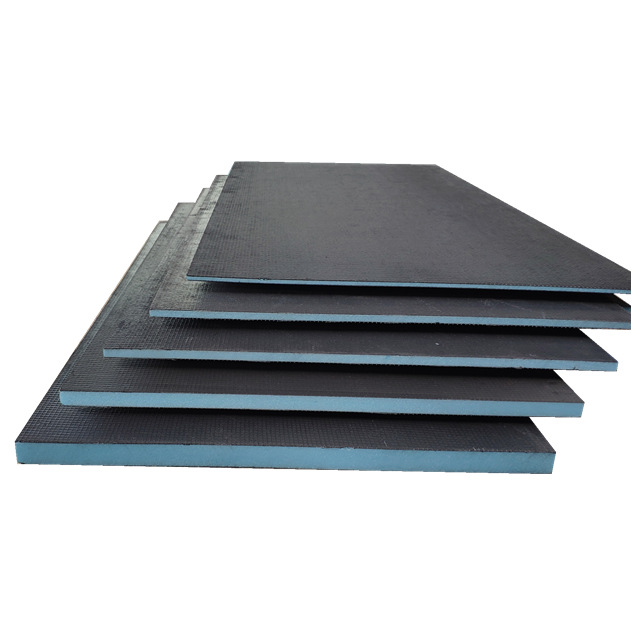

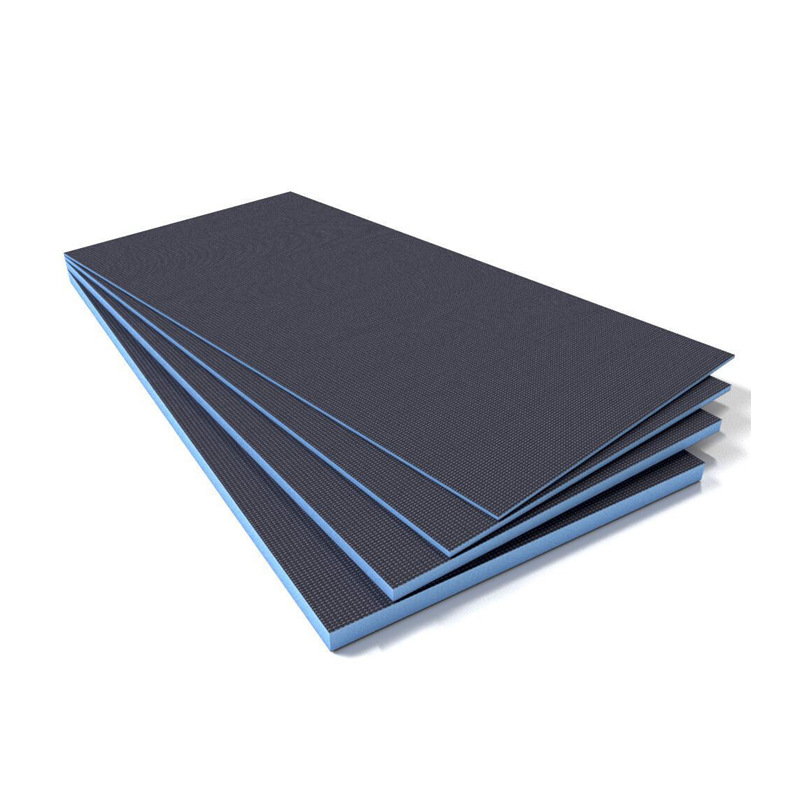

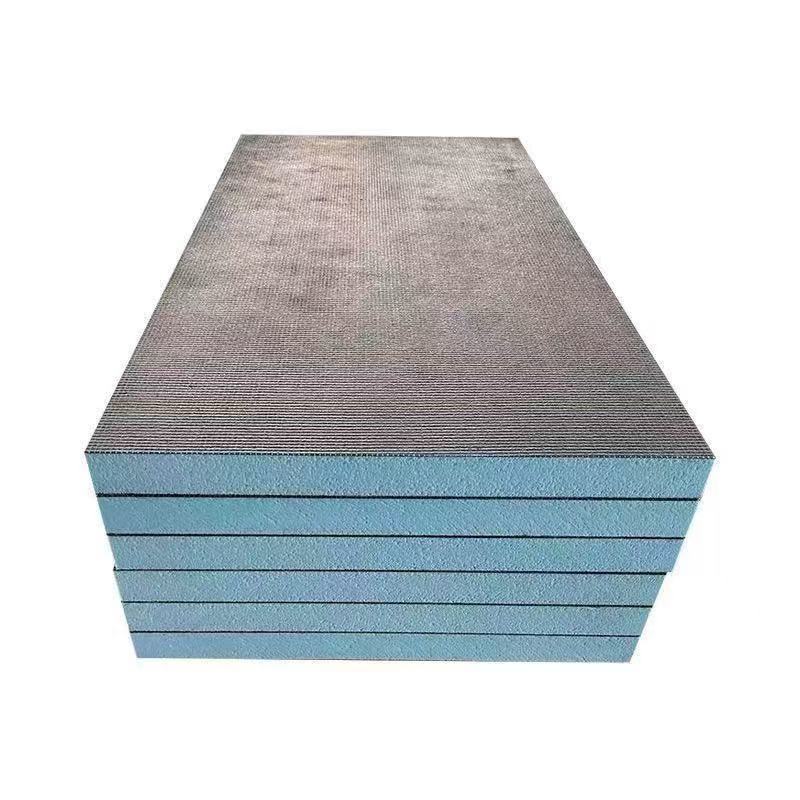

Shower Tile Backer Board

1. Waterproof & Moisture-resistant: High-density structure blocks water penetration, protecting walls.

2. Lightweight & Durable: Easy to install with high load-bearing capacity, reducing wall stress.

3. Dimensional Stability: Resists cracking and warping under temperature changes.

4. Eco-friendly: Asbestos-free and formaldehyde-free, compliant with international standards.

5. Efficient Installation: Direct tile application saves time and reduces overall costs.

Product introduction:

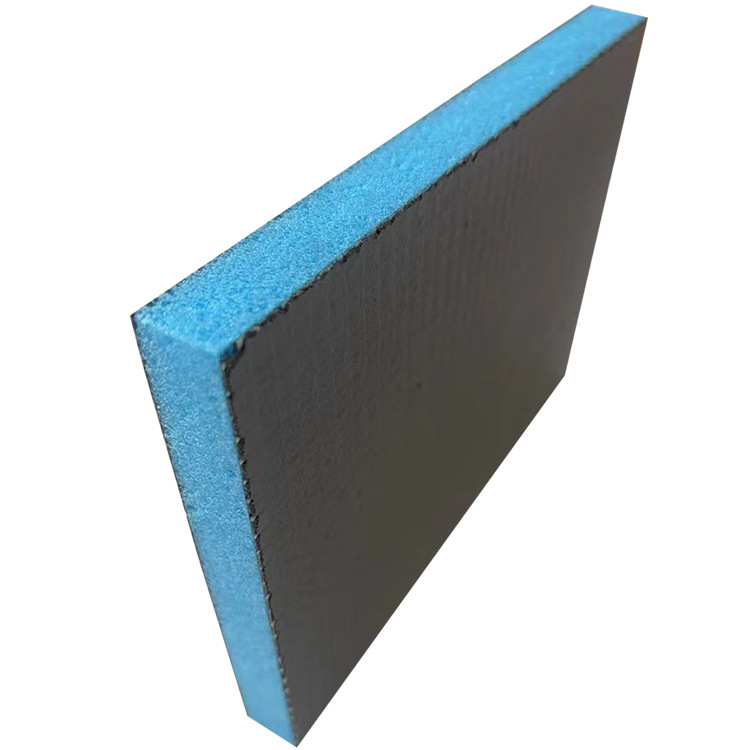

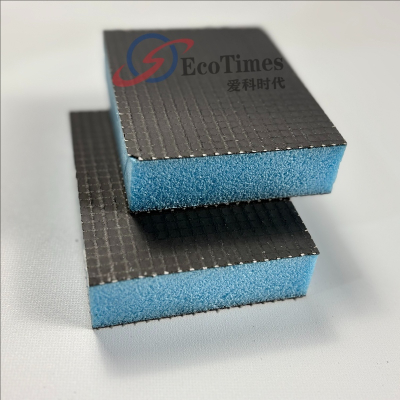

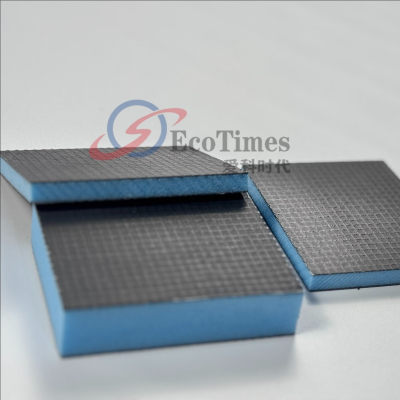

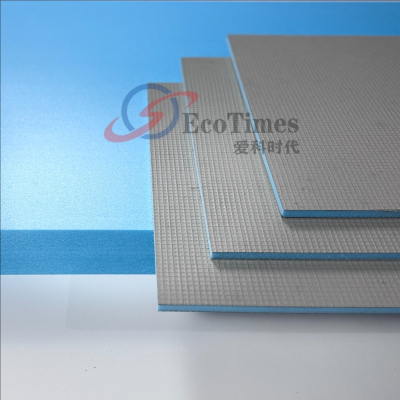

Shower tile backer board is a waterproof and moisture-proof substrate specially designed for bathroom space, adopting XPS extruded board + alkali-resistant fiberglass mesh cloth + polymer mortar composite process, which completely blocks water vapor infiltration, and solves the problem of traditional cement wall cavitation and mildew from the root. Its lightweight and high-strength characteristics can significantly reduce the load on the wall, while supporting quick installation and maintenance-free, direct tiling after cutting, construction efficiency increased by 70%, is the ideal choice for shower rooms, bathtub surrounds and other high-humidity scenes.

Product parameters:

Item | Performance Requirements |

Surface water absorption/(g/m2) | ≤300 |

Impermeability | No water penetration on the inside of the reinforcing layer |

Impact resistance/J grade | 10 |

Bending load/N | ≥1000 |

Interlayer bond strength/MPa | ≥0.40 |

Shear strength/kPa | ≥500 |

Moisture deformation/% | ≤0.07 |

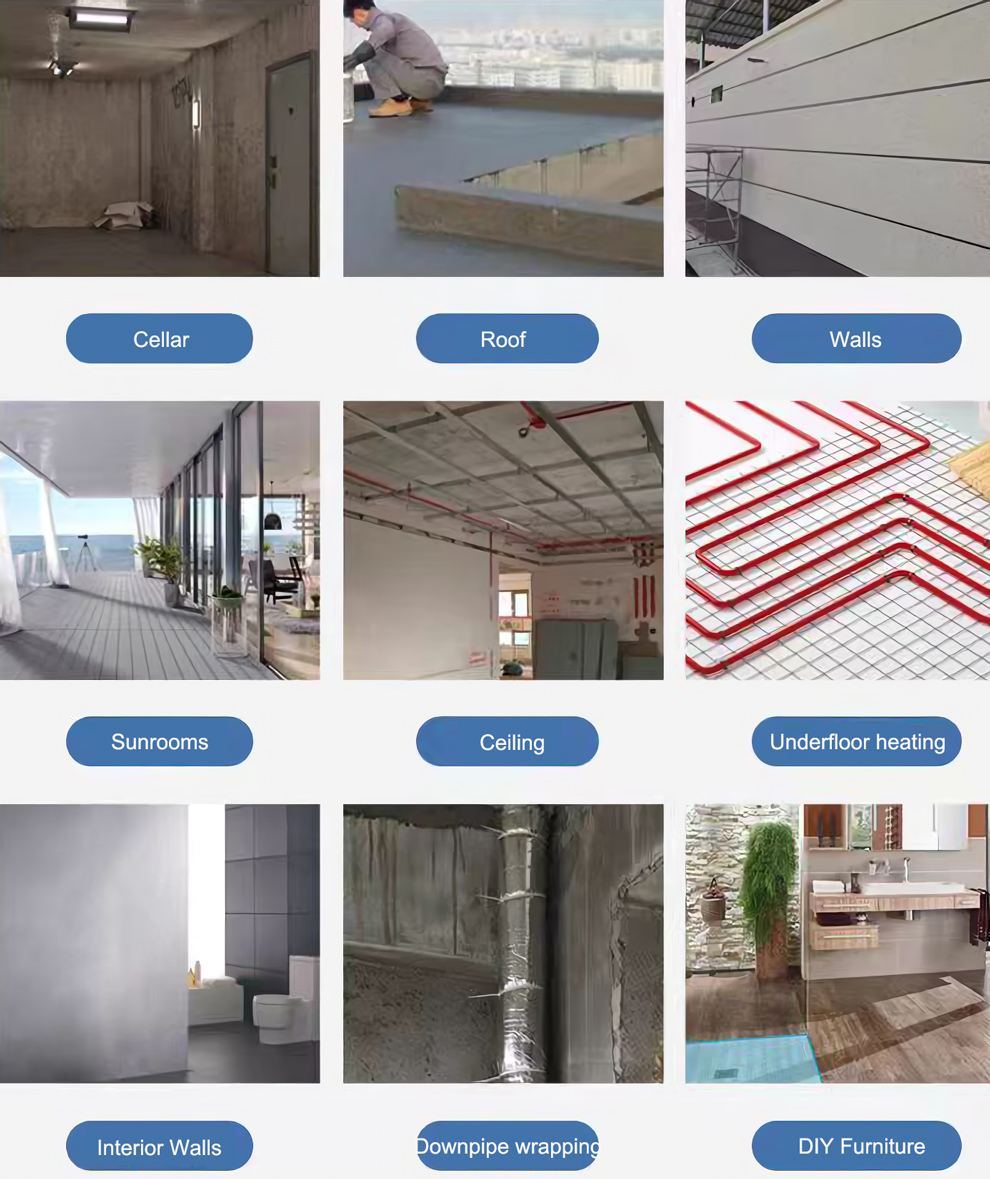

Product application:

✅ Family bathroom: wall/floor tile base, suitable for shower area, niches, concealed shower pre-built-in position.

✅ Commercial space: hotel/gym/swimming pool and other high-frequency water areas, moisture resistance life of up to 30 years.

✅ Renovation and remodeling: old walls are covered directly without demolition, saving 90% of the cost of construction waste removal.

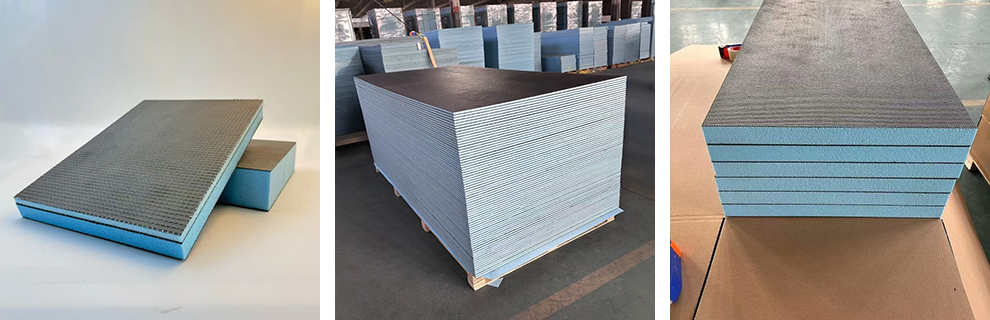

Packaging and shipping:

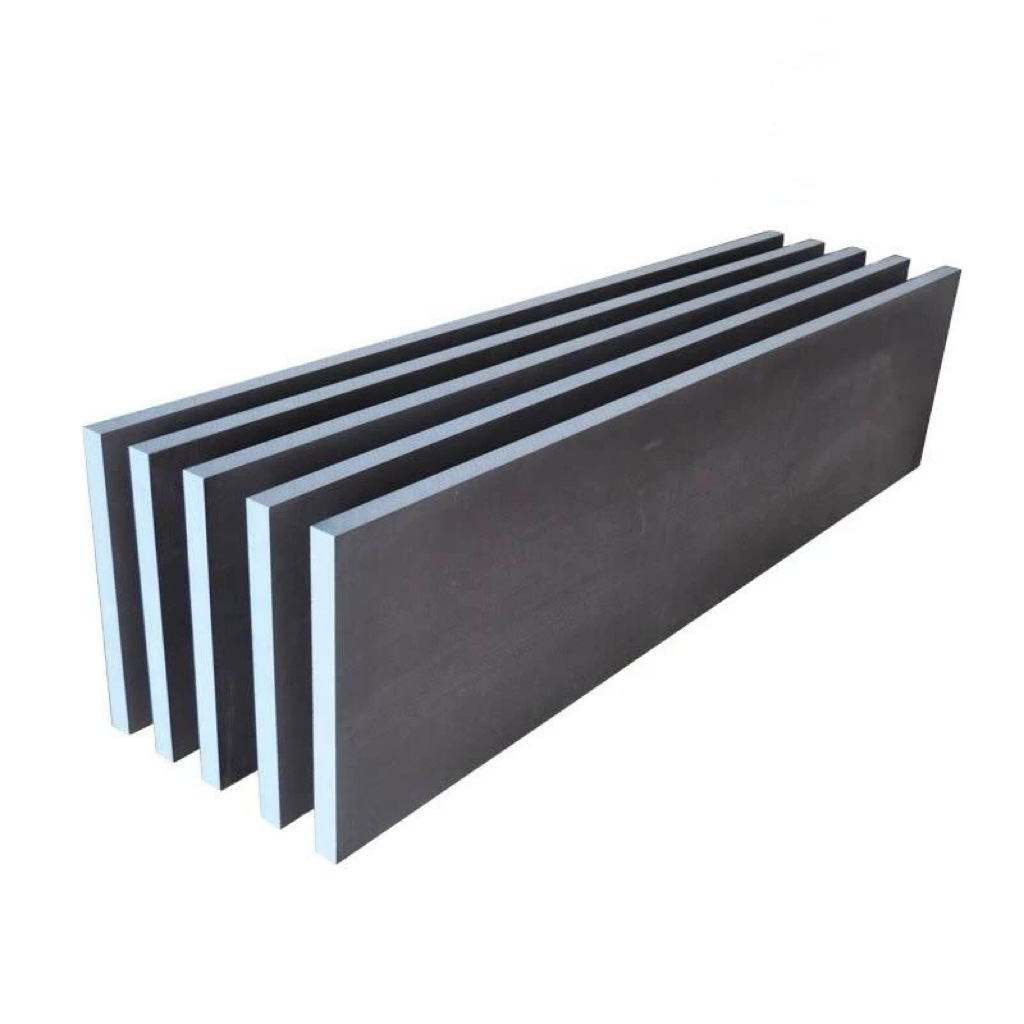

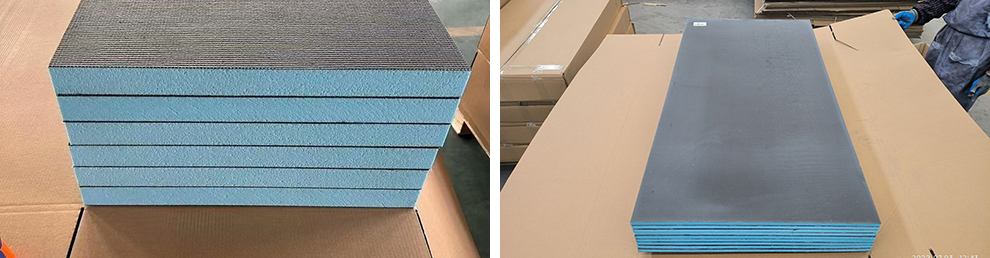

📦 Standard specification: standard specification: 1200×2400mm can be customized, thickness 95/120/200/300/500mm can be customized.

📦 Protection scheme: anti-collision corner guard + winding film + wooden pallet, anti-pressure and moisture resistance, support cross-border transportation.

Installation process:

1️⃣ Grass-roots treatment: clean up the wall surface, make sure it is flat and no loose;

2️⃣ Cutting backing board: cut according to the size, right angle/curved shape free adaptation;

3️⃣ Fixing installation: double fixing with structural adhesive + anchor bolts, waterproof tape pressed on the joints;

4️⃣ Tile Paving: direct thin paste tiles after 24 hours, no need for cement plaster leveling.

Company Strength:

As a source manufacturer, we have 100,000 square meters of intelligent production base, equipped with automatic extrusion line and quality inspection laboratory, with an annual production capacity of more than 5 million square meters. Through ISO9001, green building materials certification testing, products have been successfully applied to national projects, and provide customized solutions and full-cycle technical guidance, from R & D to after-sales escort, to help customers reduce costs and increase efficiency.