Plastering Cement Mortar

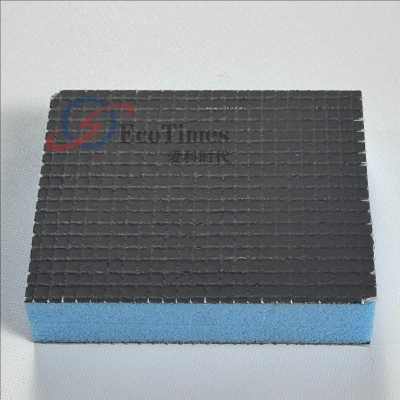

1.Anti-cracking diamond: glass fiber mesh reinforced + flexible polymer, impact strength ≥ 10J, anti-cracking than the traditional mortar to enhance the 5-fold

2.Super bonding: drawing strength ≥ 0.6MPa (2 times the national standard), EPS/XPS/rock wool boards are compatible with the whole system without drumming.

3.Waterproof and breathable: water-repellent modified formula, water absorption rate <3% while the water vapor transmission rate >15g/(m²-d), eliminating water seepage and moisture.

4.Extreme weatherability: through 100 times -25 ℃ ~ 70 ℃ freeze-thaw cycle + 3000 hours of ultraviolet aging test, life expectancy of more than 30 years

5.Thin layer fast drying: single construction thickness of 3-8mm, 4 hours table drying, shorten the construction period by 50%, the overall cost by 30%.

Product introduction:

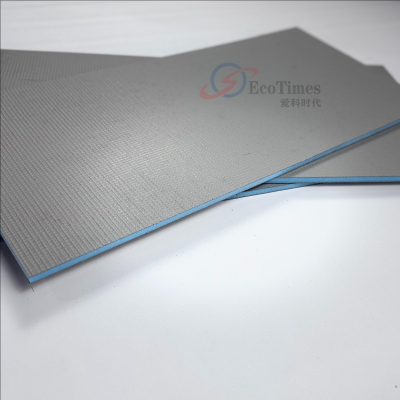

The rendering mortar is a high-quality building decoration material, which can be used as a decorative and protective material for various base surfaces such as backing boards.

It is mixed by selected cement, aggregates and a variety of additives according to a scientific formula, and has good physical and chemical properties.

Plastering Cement Mortar is a high-performance cement-based material specially used for leveling and protecting the walls and floors of buildings. It is made of high-quality cement, fine aggregates and polymer additives scientifically proportioned to have strong adhesion, anti-cracking and waterproofing, and weather-resistant and durable characteristics. Plastering Cement Mortar is suitable for internal and external wall insulation system finish layer, concrete substrate repair, moisture-proof basement and other scenarios, which can effectively improve the smoothness and strength of the grass-roots level, preventing drumming and falling off, and prolonging the service life of the building.

Product parameters:

Thickness range | 3-15mm (single layer) |

Compressive strength | ≥10MPa (28 days) |

Bonding strength | ≥0.5MPa (with insulation board) |

Applicable temperature | 5℃-35℃ construction, weather resistant -30℃ to 80℃ |

Product application:

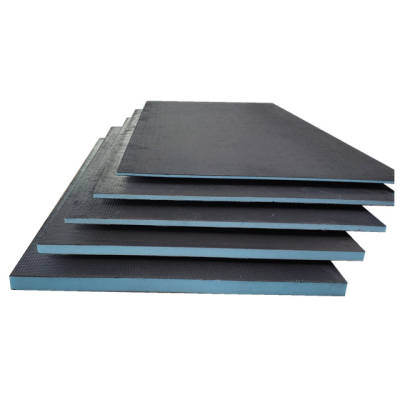

1.Exterior wall insulation system: as a protective layer for insulation boards (e.g. EPS/XPS), enhancing impact resistance and fireproof performance;

2.Indoor and outdoor walls: leveling and decorative base layer for concrete and masonry walls, suitable for coatings, tiles and other finishes;

3.Special environment: basement, swimming pool and other wet areas, play the role of moisture-proof and seepage prevention.

Packaging and shipping:

1. 25kg/bag moisture-proof woven bag, support customized ton bag or bulk;

2. Stacking height limit ≤ 8 layers, storage should be placed in a cool and dry place, shelf life of 6 months.

Installation process:

1.Grass-roots treatment: clean up floating ash, oil pollution, to ensure that the base surface is firm and dry;

2.Mortar mixing: add water and mix evenly according to the proportion, and use it after standing and maturing;

3.Layered construction: apply in layers using the thin-wiping method, with a thickness of 3-5mm for each layer, and compacted and polished after finalization;

4.Maintenance: avoid water within 24 hours after construction, and natural maintenance can be carried out for 3 days for subsequent processes.

Company Strength:

1. As a professional manufacturer of plastering mortar, we have modern production lines and strict quality control system:

2. Own factory: equipped with fully automatic batching system and dry mortar production line, with a daily capacity of 500 tons;

3. Complete certification: passed ISO9001 certification, green building materials certification, in line with GB/T 29906 standard;

4. R&D support: joint university laboratories continuously optimize the formula and provide OEM customized service;