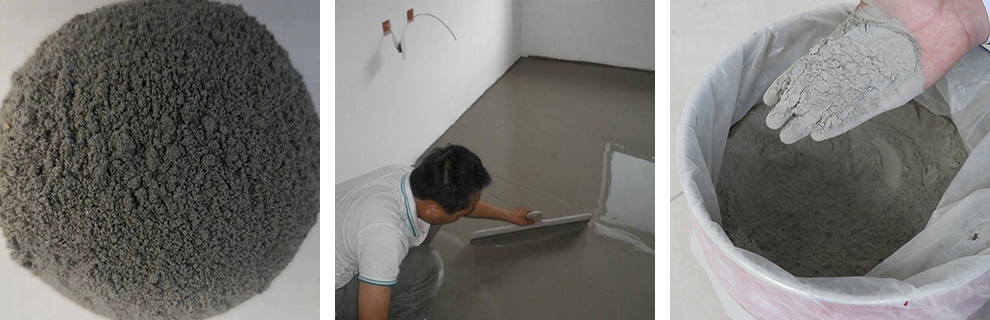

Adhesive Mortar

1.Super grip: polymer modified formula, tensile strength ≥ 1.0MPa (3 times more than the national standard), tile and stone paste no hollow drums

2.Anti-slip pioneer: open time ≥ 30 minutes, after drying slippage <0.5mm, zero fall risk of construction of slabs/rock plates

3.Extremely fast curing: 2 hours of initial strength of 0.5MPa, the next day can be loaded, shortening the construction period by 40%.

4.Compatible with glass tile/mosaic/metal plate, -10℃~45℃ environment as usual construction, 99% adaptability rate

Freeze and heat resistance: 50 times -30℃~80℃ freeze and thaw cycle test, bond strength decay rate <5%.

Product introduction:

Adhesive mortar is a high-performance cement-based adhesive specially designed for tiles, stone, insulation boards, etc. It is made of high-quality cement, graded quartz sand and polymer modification, and has the characteristics of strong adhesion, anti-slip, weathering and water resistance. As the core auxiliary material of building decoration, the adhesive mortar can realize fast bonding through thin layer construction, effectively reduce the risk of drumming and falling off, suitable for indoor and outdoor wall surfaces, floor heating floor and other high-demand scenarios, to ensure that the finishing materials are durable and stable.

Product parameters:

Tensile bond strength | ≥0.5MPa (28 days at room temperature), ≥0.3MPa (after water immersion) |

Drying time | ≥20 minutes (adjustable during open time) |

Slippage | ≤0.5mm (vertical surface construction anti-slippage) |

Applicable temperature | 5℃-40℃ construction, temperature resistance range -20℃ to 70℃. |

Product application:

1.Tile and stone paving: adhesion of wall and floor tiles, marble and granite, especially suitable for large-size bricks or low water absorption bricks;

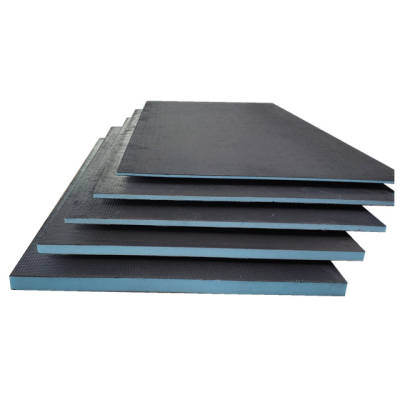

2.Exterior wall insulation system: used for bonding EPS/XPS insulation boards with the base wall to enhance the safety of the system;

3.Underfloor heating project: compatible with thermal expansion and contraction of underfloor heating environment, avoiding cracking of traditional cement pasting.

Packaging and shipping:

1.25kg/bag moisture-proof composite paper bag, support customized 20kg small package or ton bag bulk;

2.Stored in dry and ventilated environment, shelf life of 6 months, stacking height limit ≤ 10 layers.

Installation process:

1.Substrate treatment: remove loose material, ensure the grass-roots level, solid, no bright water;

2.Mortar mixing: mix according to the water-cement ratio (about 1:4) to a uniform paste, and leave it for 5 minutes to activate the adhesive properties;

3.Coating construction: scrape and coat strip mortar with tooth-shaped scraper at the grass-roots level or the back of the tile, thickness 3-8mm;

4.Paste compaction: press the material to the grass-roots level, slightly adjust the position and pat it down, and avoid weight bearing within 24 hours.

Company Strength:

1. As a professional manufacturer of plastering mortar, we have modern production lines and strict quality control system:

2. Own factory: equipped with fully automatic batching system and dry mortar production line, with a daily capacity of 500 tons;

3. Complete certification: passed ISO9001 certification, green building materials certification, in line with GB/T 29906 standard;

4. R&D support: joint university laboratories continuously optimize the formula and provide OEM customized service;